Your premium log cabin with the most advanced modern log structures!

GIANTLOG provides a completely new kind of modern, smooth and sleek log wall surface that minimizes seams between the logs. The 360-millimetre-high GIANTLOG element allows you to build a one-storey house using only seven log elements on top of each other per wall. This is many times faster, more cost-efficient and ecological compared to the traditional 260-millimetre-high log elements.

If traditional look is nevertheless preferred, even the highest GIANTLOG element can be delivered with grooves to make it look like traditional log wall. Whether you prefer the traditional or modern look, you can still reap the benefits of using the most advanced log structures in the market!

Thanks to its great mass, the sturdy GIANTLOG enables wider and more open room spaces without the need for separate pillars to support the structure. It is the perfect solution for building homes and cabins, but even more so, it offers completely new possibilities in large construction projects, such as schools, care facilities and hotels.

Giantlog – the perfect frame for luxury homes

A magnificent complex of Giantlog houses has been built in Vartiokylä, Helsinki, by construction company Argentum. The complex includes three semi-detached houses and one 180 m2 single-family house. The level of finishing and material choices in the destination is astonishing, therefore the naturally impressive Giantlog was chosen as the frame of the houses.

Because GIANTLOG is a truly non-settling log structure, it can be easily combined architecturally with other non-settling materials, such as stone, concrete and glass. What enables GIANTLOG to avoid settling is its special profile, a specific drying technique as well as the method of using a specially dried laminated beam at the core of the log. This advanced log structure makes use of timber's natural load bearing properties in the optimal manner and minimizes structural tension within the element.

Thanks to the non-settling structure of GIANTLOG, it is no longer necessary to manually adjust the log frame of the building as the building settles over time. With traditional log structures, this is still necessary today.

GIANTLOG is, as the name suggests, significantly higher than traditional log elements. GIANTLOG is available in the following dimensions: 150, 200, 250 or 300 millimetres thick and 360 millimetres high. Because the elements are higher, you need fewer logs on top of each other when assembling a house. Thus, with the GIANTLOG element, building a one-storey house requires only seven log elements per wall. When using a standard 260-millimetre traditional log, to reach the 3-metre ceiling height of a one-storey house, 12 logs are needed per wall. When you choose GIANTLOG, this means less hoisting, less seams and less time consumed in assembly. Faster, more cost efficient and more ecological. And because assembly is faster, it is easy to make sure that all the structures stay safe from rain and moisture during construction.

The non-settling GIANTLOG makes it possible to build a log house with sleek and modern corners, enabling the use of the ecological log in the city and the suburbs where house designs and building materials may be relatively strictly stipulated by the local Building Code. This so-called city corner does not require corner boards and looks great without.

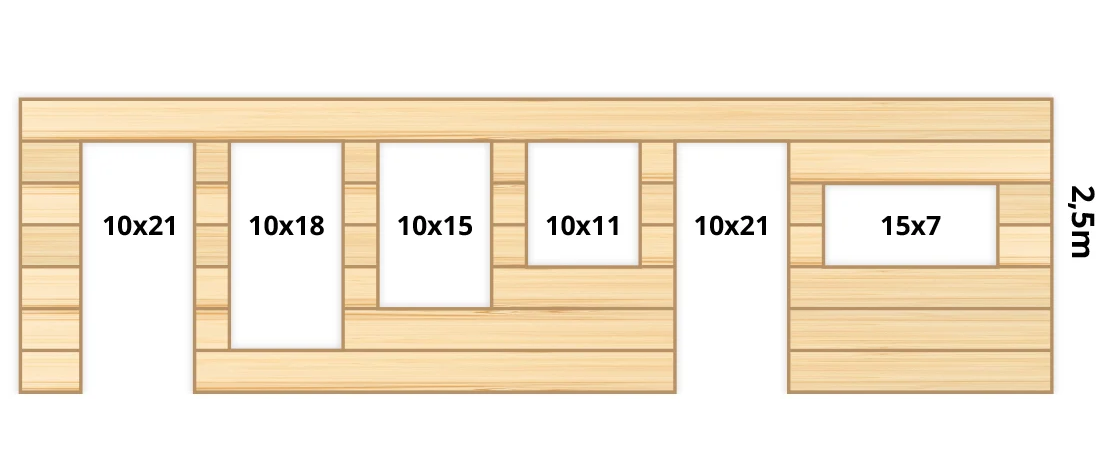

One important consideration during the design of GIANTLOG was minimizing waste during the construction process. With GIANTLOG, the log house is assembled as if using building blocks. The three available profile heights have been selected to suit most common door and window sizes without necessitating cutting. All opening sizes are nevertheless possible, and even when an unusual opening size is preferred, making the necessary cut to the nearest profile height will minimize waste.

One commonly used solution nowadays is CLT or cross-laminated timber. The module height for CLT elements is on the average 3 metres, and for higher living rooms and halls, multiple elements are installed on top of each other. GIANTLOG can also be delivered in giant elements that are quick to transport and install, but with GIANTLOG, the size is more adjustable and thus there is less waste. The cubic price of CLT and GIANTLOG is approximately the same but with GIANTLOG, the customer pays only for the material that is used.

GIANTLOG is manufactured using Nordic spruce or pine from sustainably maintained, PEFC-certified forests located in Finland, Sweden and Norway. Nordic spruce and pine were selected as the material because of their excellent structural and Scandinavian visual properties. When grown in the harsh conditions of the north, the trees grow to be sturdier and more tight-grained than their southern counterparts. Their chipping is minimal in extreme strain.

A tough and hard building material, spruce is also visually appealing. It provides an even, light-coloured surface that caters well to modern Scandinavian design aesthetics. It will retain its beautiful light hue over time.

Pine, commonly used in traditional log construction, as a material has branches stand out darker and larger compared to spruce. The shade of pine is slightly darker and warmer. Both species have their own good points, and in the end, the choice can be made according to your own preferences.

Living in a log house is comfortable, as the building breathes and finds a natural balance with heat and moisture. The naturally insulating and breathable log contains the building’s structure, as well as inner and outer surfaces in one package. This is why the breathable log as a material is perfect for adjusting to changing temperatures outside, naturally balancing indoor conditions.

Because there is only one material without any surface layers, there is no risk of detrimental microbes or molds developing. Even the glue that is used in manufacturing GIANTLOG is non-sealing, breathable and does not contain formaldehyde.

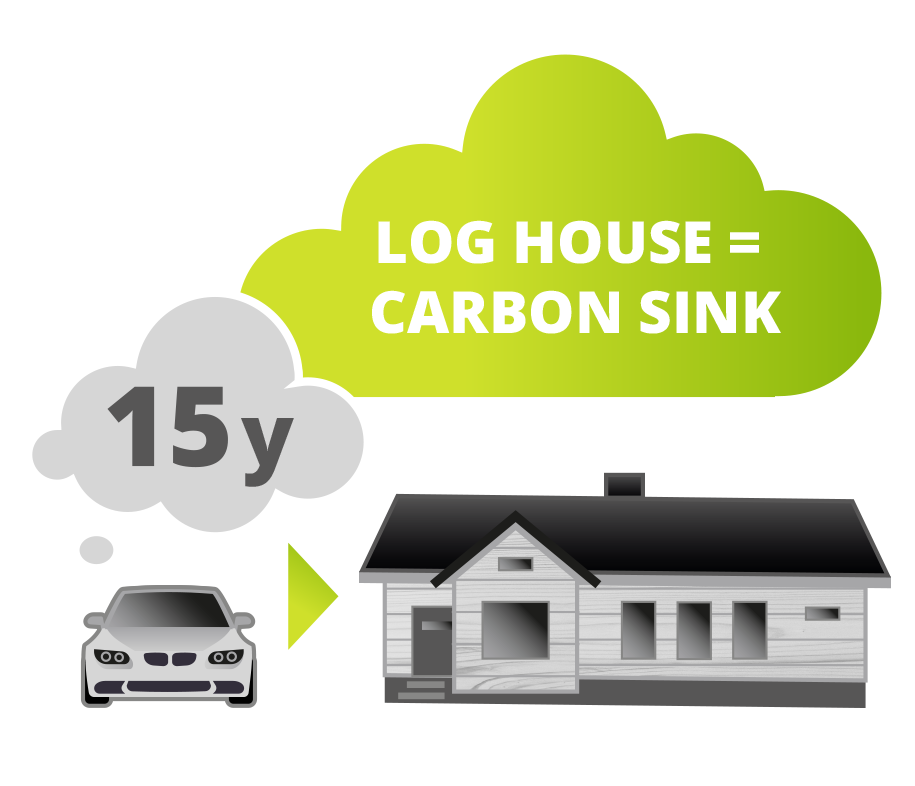

Log construction has a positive carbon handprint. When you fell a fully-grown tree in a well-managed forest to produce logs, the carbon stored in the log remains bound in the log throughout the log’s entire life cycle. In this way, GIANTLOG is a massive repository of bound carbon.

Using responsibly produced timber for construction preserves natural resources and slows down climate change. Efficiently managed forests with young, growing trees are efficient carbon sinks.

According to the log's environmental product declaration calculated by the Natural Resources Institute Finland, the log walls of a medium-sized (150 m2) log house bind 30,000 kilos of carbon dioxide. This carbon dioxide offset compensates for the use of the family's internal combustion engine car for more than 15 years (RTS EPD 31_19, 14,000 km/year, 135 g CO2/km, source: Finnish Log House Industry).

The amount of raw wood needed for one log house will grow in a Finnish forest in less than a minute on a summer day.

The production of GIANTLOG is environmentally sustainable, meeting the requirements of the PEFC 2002:2013 certification regarding the chain of custody of timber, as indicated by the PEFC label on our products. This makes GIANTLOG a responsible and sustainable choice with prefabricated houses and construction projects.

What enables GIANTLOG to avoid settling is its special profile, a specific drying technique as well as the method of using a specially dried laminated beam at the core of the log. This advanced log structure makes use of timber's natural load bearing properties in the optimal manner and minimizes structural tension within the element.

With GIANTLOG, you can build completely new kinds of log buildings, with modern sill-less windows, doors without covering strips, as well as sleek and minimalist house corners without the traditional log house corners. These are no longer needed because the GIANTLOG does not settle. The traditional settling log leaves open spaces between structures as it settles, dries and shrinks, necessitating the use of large windowsills and various covering strips to cover the gaps.

Image: Principle of how GIANTLOG minimizes waste. Percentage of wasted material during construction is only 2-4 %.

What kind of log home are you dreaming of? We have created the GIANTLOG house collection in collaboration with architects specializing in log buildings. Be inspired by our collection or ask for a quote based on your own plan!

Get a completely individual log house, with a high-quality finishing, using the latest production technology. Design a log home or log villa that fits your needs and is perfect for your plot.

The developer of GIANTLOG, Pellopuu manufactures each GIANTLOG element using one of the world’s largest Hundegger timber lines representing the absolute cutting edge within the field.

GIANTLOG elements are CE and PEFC certified and are in accordance of the international SFS-5973 log construction standard and the European EN 14080:2005 timber construction standard. Pellopuu is ISO 9001:2015 certified for quality management. Pellopuu has a patent pending for the GIANTLOG structure.

The partners of Pellopuu are responsible for the international sales of GIANTLOG to both consumers and construction companies.

Contact GIANTLOG sales today and ask for a quotation!